Wire Division

Types of wire rope

Wire rope consists of several strands of metal wire laid. It is important to select types of wire rope after understanding product features.

- SG (1×19)

A rigid wire rope used for linear push-pull movements.

A rigid wire rope used for linear push-pull movements. - SA (3×7)

A wire rope with basic configurations.

A wire rope with basic configurations. - SE (1×7)

A basic unit of wire rope.

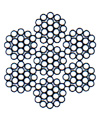

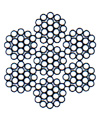

A basic unit of wire rope. - SC (7×19)

7×19 wire rope is more flexible and more fatigue resistant than 7×7. (Suitable for the driving pulley)

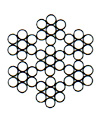

7×19 wire rope is more flexible and more fatigue resistant than 7×7. (Suitable for the driving pulley) - SB (7×7)

7×7 is a wire rope consisting of 7 strands of 1×7 wire rope.

7×7 is a wire rope consisting of 7 strands of 1×7 wire rope.

Nylon coating

- NSC (7×19) nylon coating (color:translucent)

Compared to 7×7, it is flexible and excellent in fatigue characteristics. (ideal for driving via a pulley)

Compared to 7×7, it is flexible and excellent in fatigue characteristics. (ideal for driving via a pulley) - NSB (7×7) nylon coating (color:translucent)

A standard configuration combining seven 1×7.

A standard configuration combining seven 1×7.

Materials

| SUS304 | A most common material with corrosion resistance, heat resistance, and excellent mechanical properties. |

|---|---|

| SUS316 | Coated with molybdenum, having more corrosion resistance and acid resistance than SUS304. (※Please contact us for the availability of SUS316) |

Information on technology: stainless steel wire rope

How to twist wire ropes

|

There are two different types of twist wire ropes. Z twist is commonly used. |

Coating

A coating wire rope maximizes metallic feature.

| Nylon 12 | Nylon 12 is used for driving wire rope to increase flexibility and abrasion resistance.

* Please refer to Wire Specifications for further information on diameter of SB(7×7)・SC(7×19)after coating. |

|---|---|

| Dia X | A combination of Nylon and carbon increase fatigue resistance.

For further information on stocks of coated wire ropes, please contact us. |

| Teflon | Teflon has chemical resistance and heat resistance.

* For further information on stocks of coated wire ropes, please contact us. |